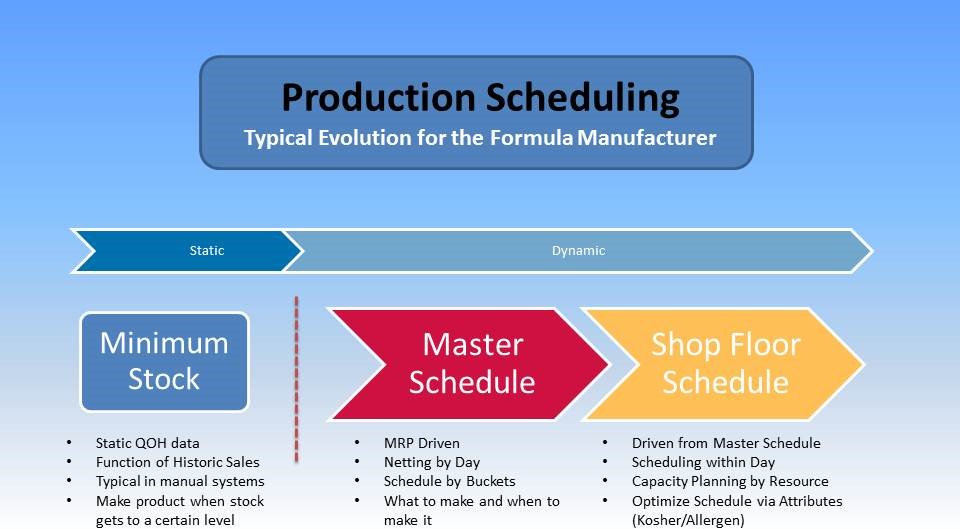

From my perspective, companies evolve into their production scheduling process as their business evolves. Attempting to implement a complex master production schedule model when a company is beginning to automate their ERP manufacturing process is often a mistake. The key is to take a realistic view of what stage the company is in and grow from there.

Minimum Stock As a production schedule

Formula manufacturing companies often start fairly manually with a Minimum Stock model. When quantity on hand or expected quantity available falls below a certain level, a batch ticket is requested. This works well for small manufacturers with predictive sales. The key problem with this model is that there is no time sensitivity. A sales order for tomorrow is required, as is the order for next week. All quantities are lumped into a single bucket and minimums are based on historical sales values.

Master Production Schedule Drives the production schedule

As the manufacturer grows, they want to look out into the future and generate a Master Production Schedule. They will start to consider sales orders or sales trends (not just 100 units per month) in their calculations. They will consider over-runs in production and shortages in planning future runs. This is a basic MRP design. The result is a list of items to be manufactured over time (not just right now). These companies schedule the floor manually and the production managers will be looking 1-2 days out and moving jobs around as they see fit. Visibility into the order in which jobs will be run is limited.

Shop Floor Scheduling in the production schedule

Finally, when the process manufacturer gets to Shop Floor Scheduling, they are now concerned with the capacities of machines and scheduling downtime. They consider run times and setup/cleanup times in the schedule. The order in which products run becomes important. Grouping allergens together and Kosher products on specific days of the week become significant scheduling challenges. The scheduler is often making these decisions in each of the previous stages but now it is documented so others can see the result. Feedback from the floor is now possible. If a job is running late, the operators can record that in the schedule and corrective action can be taken.

So basically, there is no wrong answer to scheduling. You need to determine where you are in the life cycle and purchase accordingly. Microsoft Dynamics™ inventory functionality can handle the basics. Vicinity Software steps in for MRP and generation of a Master Production Schedule and Planet Together finished out the scheduling with Shop Floor Scheduling.

The takeaway here is to buy today what you need today with an eye to the future. Vicinity coupled with Microsoft Dynamics and Planet Together is a great way to invest in your company’s future for many years to come.

Additional readings: