Top 6 Vicinity Software product features of 2022

Let’s take a quick look at some of our favorite features added to our Vicinity Software product in 2022 for VicinityChem, VicinityBrew and VicinityFood clients.

Thanks to the development team for their hard work this year. Some of these features were inspired by customer feedback and others were part of the natural evolution of the software as part of the development roadmap.

Here’s our Top 6 list of features from 2022:

Release 4.37 Mass Production Maintenance

Mass Production Maintenance is a new Production Control feature. It is used to release, delete and ops-close batches in bulk.

——————————————————–

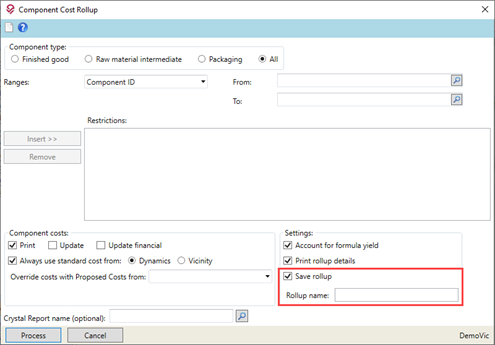

Release 4.38 Saved Detailed Component Cost Rollup Results

The detailed results of a Component Cost Rollup (CCR) can now be optionally saved to a SQL table for future reporting. This function is available through the Component Cost Rollup screen or from the VicinityView tool.

The saved CCR can be reprinted through VicinityView >> Reports >> Product Development >> Saved Component Cost Rollup.

——————————————————–

Release 4.38 Bulk Edits of Planned Orders

This feature was prompted by customer feedback and gives the user the ability to perform bulk edits.

——————————————————–

Release 4.39 Tool Tip Enhancement in Production Calendar

The tooltip that is displayed when a user hovers the mouse over a calendar batch or planned order has been expanded to display additional information in the Production Calendar and Production Schedule. Specifically, the tooltip now includes the Batch/Planned Order Number, Start Date, Finish Date, Formula, Component Description, Quantity Ordered, UOM, Planned Order Notes, and Batch End Item Notes.

Check out this video for more information.

——————————————————–

Release 4.40 Component Stocking UOM Change Utility

Previously, once posted transaction history existed for a component it was not possible for the user to change the stocking unit of measure through the user interface. With the introduction of the Component Stocking UOM Change utility, the user is now able to change the stocking unit of measure. The utility will update:

-The component stocking unit of measure

-The stocking unit of measure for any Formula Mix/Fill Procedures and Component BOMs

-The required stocking unit of measure quantity for any Formula Mix/Fill Procedures and Component BOMs, according to the selected options

-The existing Alternate Unit conversions

Check out this video for more information.

——————————————————–

Release 4.40 Component/Formula ID Change Utility

The utility allows the user to change the Component ID and Component Description. A comment can also be entered which will be recorded in the change log. Running the utility will update the Component ID in all impacted tables.

The Change Log Detail table will track changes to the following records:

-Component BOM (SubComponentId)

-Component Reportable Components

-Formula Fill Procedures

-Formula Mix Procedures

-Formula Reportable Components

———————————————–

For more information about any of these features or to schedule a demo, contact us today!